Servo Drives

Operation

Remote Service Support

Interface

Set-up and automation

Servo Drives

- Very high dynamic behaviour of the stroke and infeed axis, leading to fast movements and precision reversals

- Rigid, heavy-duty backlash and maintenance free precision reversals

- High machining precision

- Low space requirement due to compact design without additional hydraulic unit

- No hydraulic oil or costs for maintenance, servicing, oil change, storage and disposal

- No thermal pollution of the environment from hydraulics

- Low noise emission

- Energy saving

- Position detection in the drive motors

- Easy maintenance and service

Easy plug-in installation to your machine

Online technical support and assistance

Avoiding extensive travel costs

Ethernet or 3G/4G-connection available

Demonstrable reduction of downtimes

Remote Service Support

The FRÖMAG Remote Support Router reduces costs and increases response time for the availability and maintenance of your FRÖMAG machines demonstrably. After plugging in, the Remote Router connects the machine via Ethernet or GSM to the web. FRÖMAG service connects to the machine remotely for technical support, assistance or trouble shooting.

The key points at a glance:

• Easy plug-in installation to your machine

• Ethernet or GSM-connection available

• FRÖMAG connects to machine

• Online technical support and assistance

• Demonstrable reduction of downtimes

• Cost-effective avoiding travel time

Safety first:

Strong end to end encryptionm two factor security authentication and standard measures to reduce risks of vulnerabilities are put in place. The machine can be disconnected or put offline as you require any time.

Get your quote:

Simply send us the Serial Number of your machine. In return you get a quote including a brief step by step explanation, how easy the upgrade procedure is.

Order your router

Send us your order in case you want to benefit from the advantages of our Remote Service Support.

Plug in and connect

After unboxing the remote router is plugged into the machine control cabinet. Any time you like to disconnect the machine simply unplug the router.

Remote maintenance

Interface

Digitalization, new communication technologies and technical developments demand ongoing, continuing education in order to maintain our leadership position. FRÖMAG rises to this challenge every day.

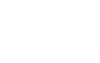

RFID

Up to 15 operators can be managed. The operators are divided into four groups. Each operator can be assigned up to 10 different access rights to the various parameters and functions of the control.

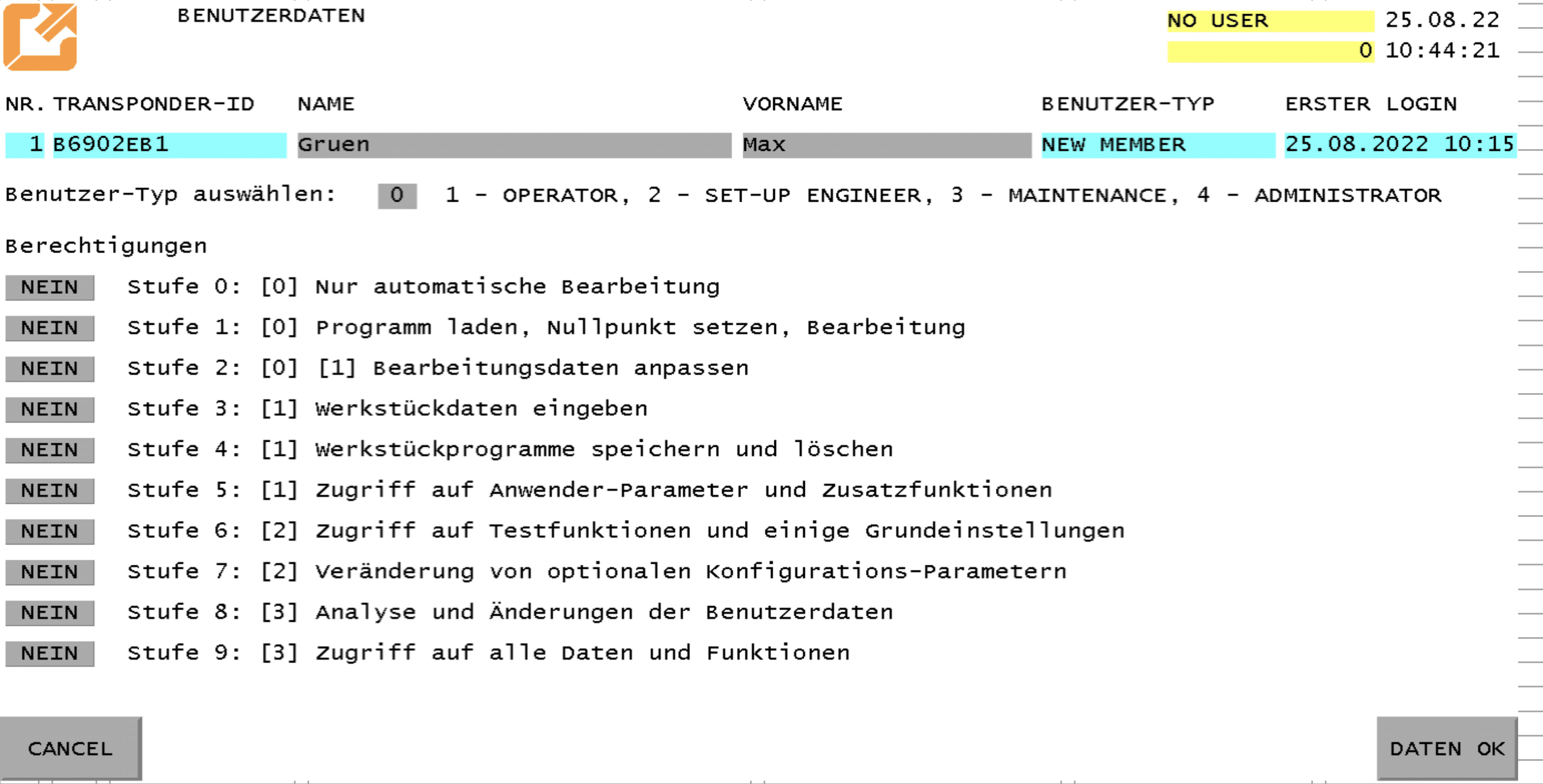

Energy Monitoring

- Display of the current energy consumption

- Total consumption recording

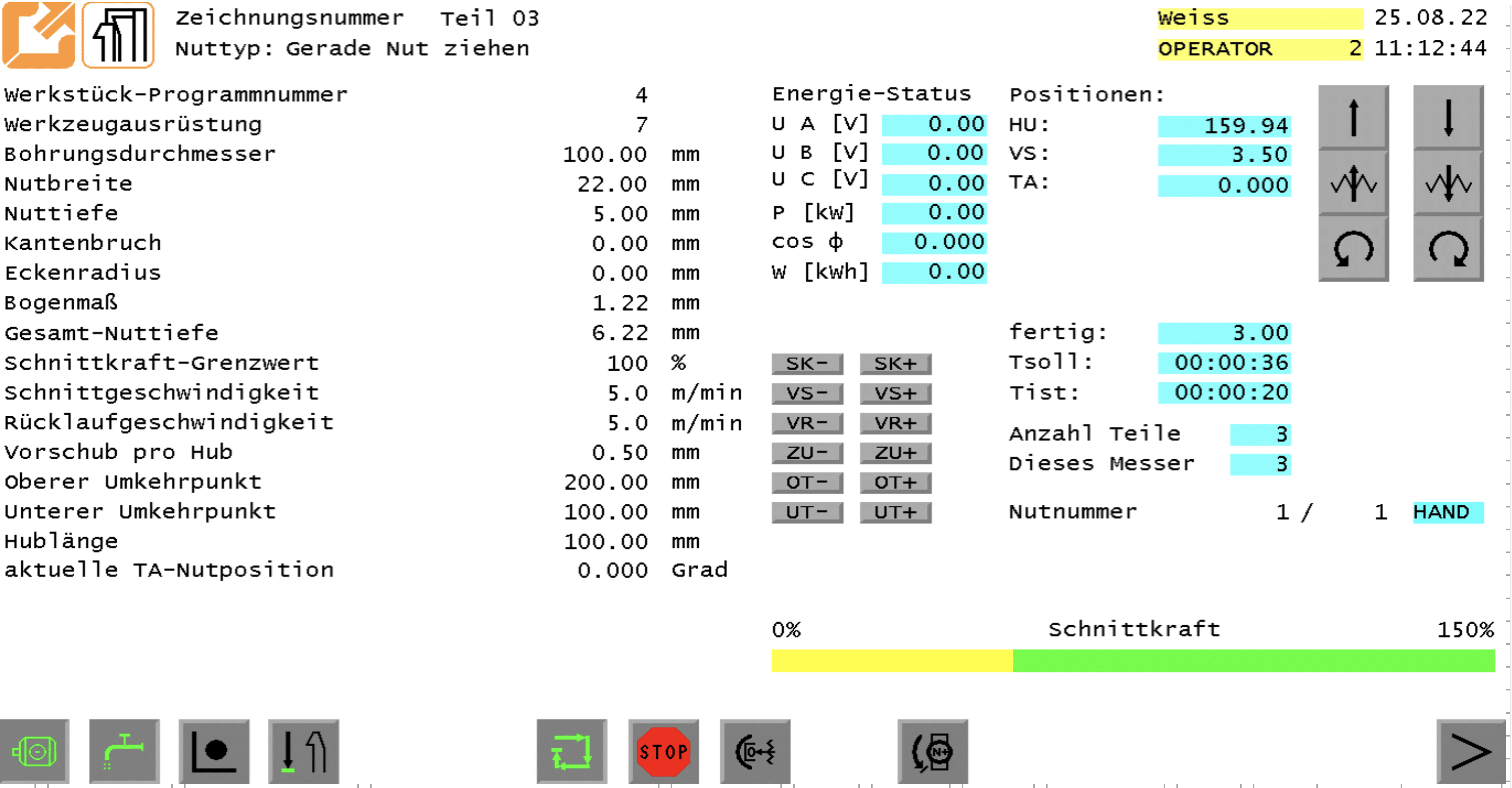

OPC-UA

Following machine data are sent:

- Machine status

- Machining time

- Machining progress

- Active machining programme

- Operating hours

- Machine state error

Additional data / parameters on request

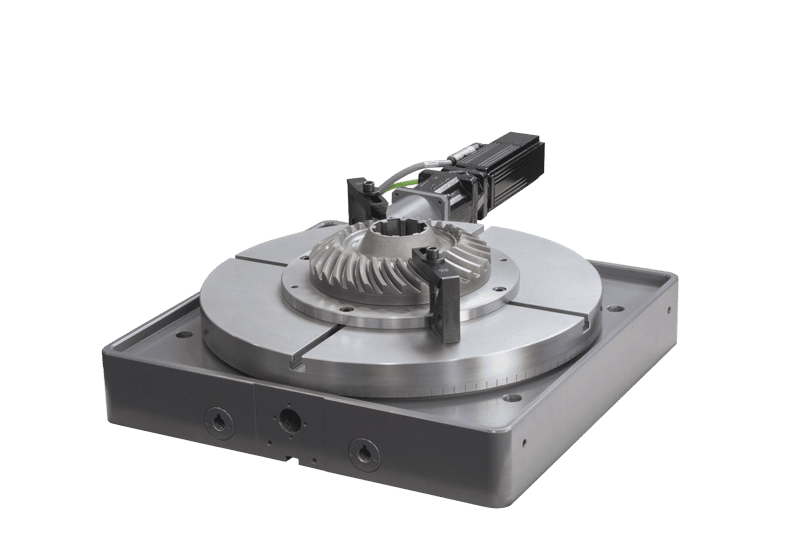

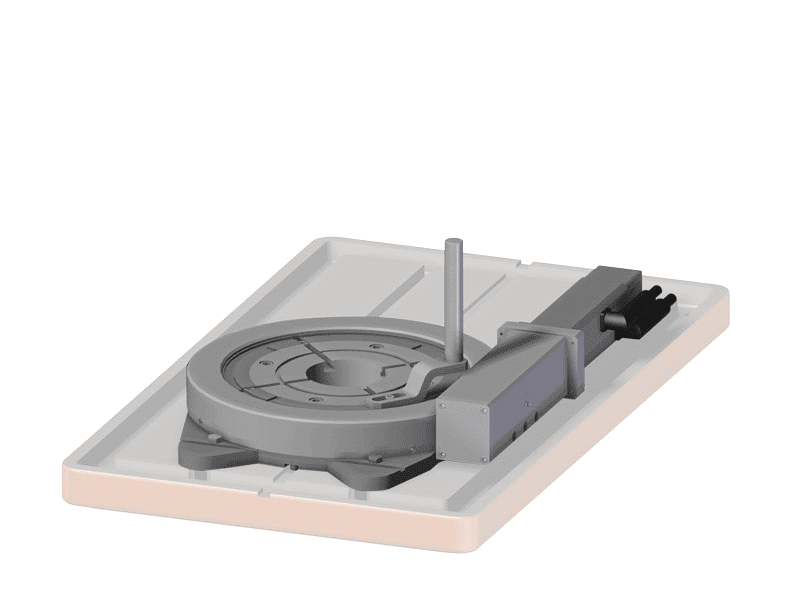

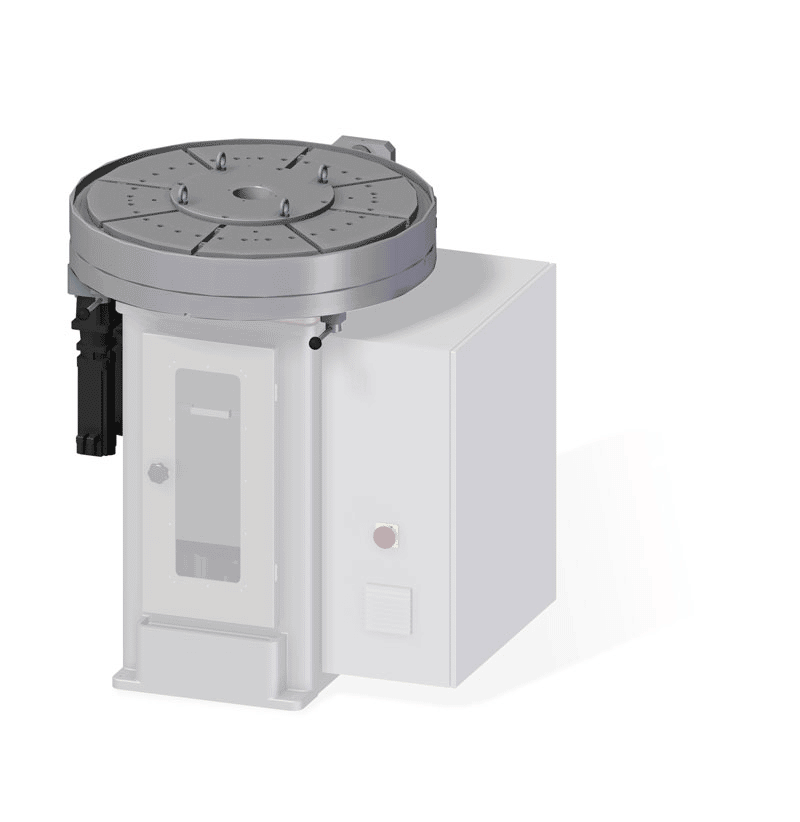

Equipped with Indexing tables

FRÖMAG manual and automatic indexing tables are available, depending on design, for bores from 10 – 900 mm.

FRÖMAG indexing tables are used, for example, in the production of internal splines according to DIN 5462/5472 or other standards, multiple keyways, helical gears, and other profiles or keyways apart from each other.

Manual indexing tables are available for bores up to 400 mm and can be equipped for direct or indirect division.

Automatic indexing tables are driven by servo motors. The computation (indexing) is effected electromechanically and controlled by the main machine CNC. The data is input at the touch screen of the control panel.

Automatic Indexing tables, starting with the model TA400A and larger, are equipped with two servo drives (Master and Slave). This mode of drive allows a backlash free revolution of the rotary table enabling the machining of internal helical splines.

TA 290 Automatik

TA 180 Automatik

TA 400 Automatik

Quick and easy Set-up

Advantage of the FRÖMAG clamping system:

FRÖMAG clamping systems feature a variable height setting in the equipment in order to react flexibly to the vast variety of workpieces.

Automation keyseating

and profiling machines

FRÖMAG clamping bridge combined with indexing table. All clamping bridges can be equipped with robots and portals for feeding.

Automatic workpiece

recognition

Automatic workpiece recognition, no contact, no manual measuring, no additional input in control

Automation

broaching machines

Automation FRÖMAG broaching machines

Machines can be equipped with robots and portals for feeding

Automation short

stroke broaching