Keyseating

and profiling machines

Broaching machines

Special machines

Procedures

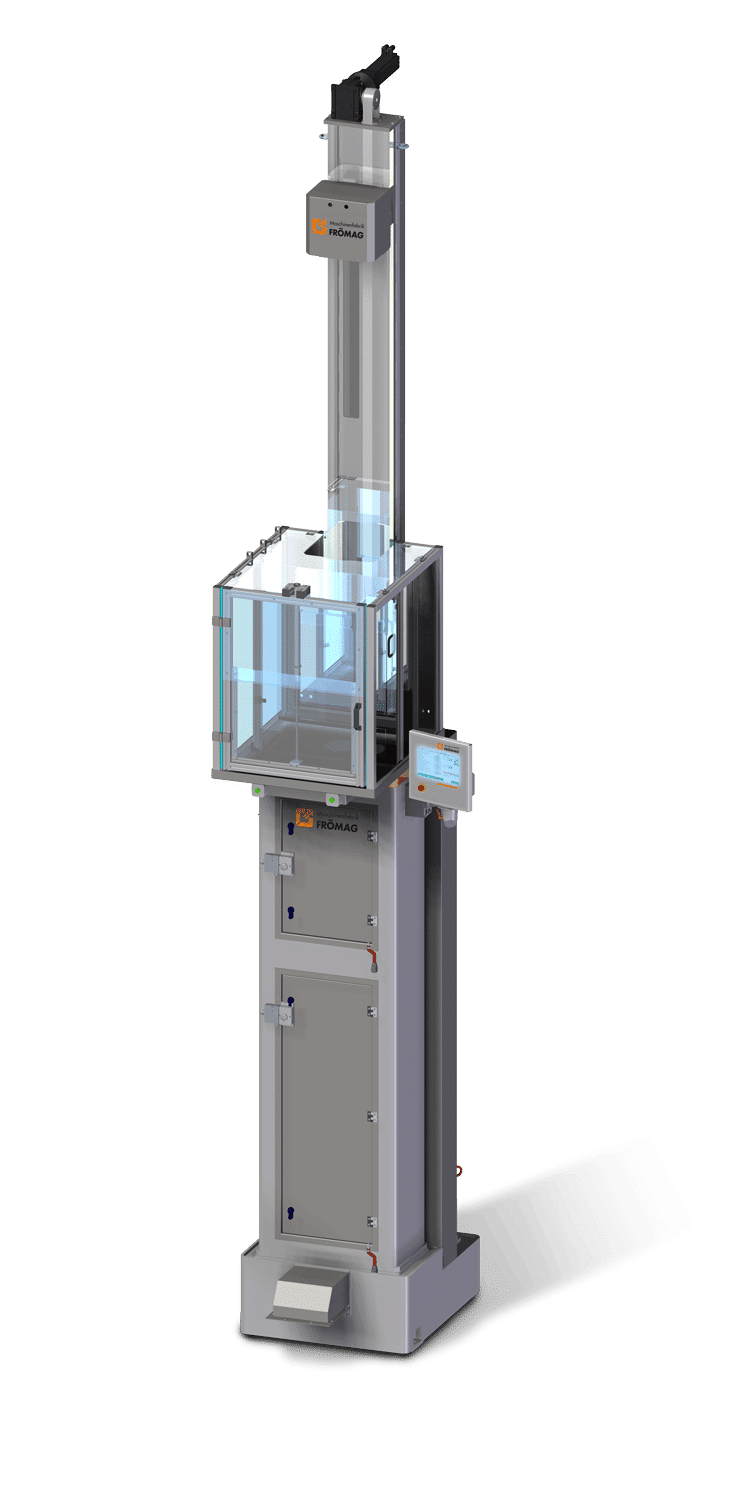

Keyseating and profiling machines

Type »Rapida E«

- Type »Rapida E-3+E-4« Features

- Type »Rapida E-3+E-4« Technical details

- Type »Rapida E« Tooling and additional equipment

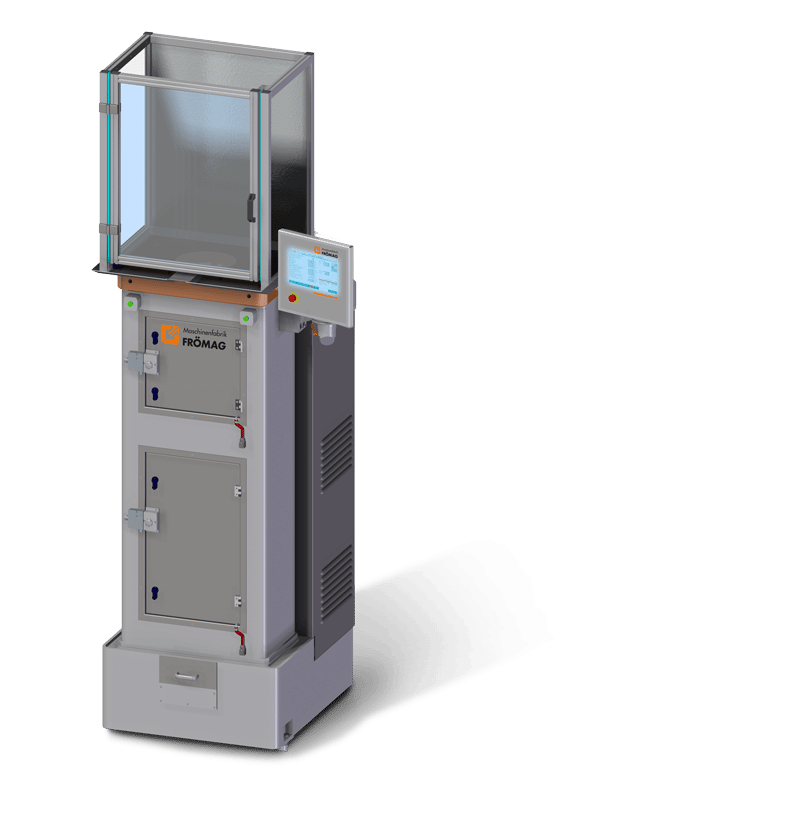

The innovative FRÖMAG electromechanical keyseating and profiling machines work with the highest quality, and with excellent efficiency using high dynamic servo-drives.

- Very high dynamic behaviour of the stroke and infeed axis, leading to fast movements and precision reversals

- Low overall height for keyway lengths up to 600 mm

- Low space requirement due to compact design without additional hydraulic unit

- No hydraulic oil or costs for maintenance, servicing, oil change, storage and disposal

- Extended tool life and improved surface finish due to high running smoothness

- Low thermal and noise emission

- No separate position detection, as it’s already included in servo-drives

Rapida features:

- Intuitive control with 15-inch display, available in a large number of languages

- Workpiece recognition, no contact, no manual measuring, no additional entries required in the control

-

Benefit of the FRÖMAG clamping system:

FRÖMAG clamping systems feature a variable height setting in the equipment in order to react flexibly to the vast variety of workpieces. -

Remote support interface

Options:

- Automation

- Interlinking

- Clamping bridge

- Indexing tables

- Machine data via OPC-UA

- RFID Tagreader

Please contact us for further information.

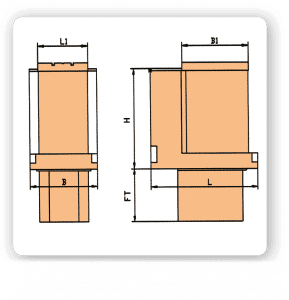

| E 32-3 | E 50-3 | E 70-3 | |

| Keway width (mm) | 2 – 32 | 2 – 50 | 2 – 70 |

| Keyway length (mm) | 425/600 | 425/600 | 425/600 |

| Bore size | 10 – 130 | 10 – 230 | 10 – 500 |

| Cutting- and Return Speed (m/min) |

0 – 15

|

0 – 15 0 – 30 |

0 – 15 0 – 30 |

| Infeed rate/stroke (mm) | 0,01 – 1,5 | 0,01 – 1,5 | 0,01 – 1,5 |

| Loading Capacity (kN) | 300 | 350 | 350 |

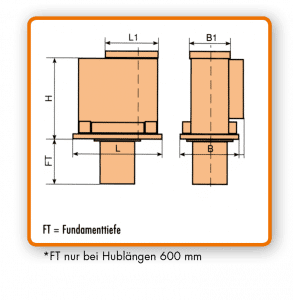

|

Machine dimensions

|

1290** 1100 930 250 |

1290** 1100 930 250 |

1310** 1100 930 250 |

| Machine Table Size L1 x B1 (mm) | 640 x 600*** | 640 x 600*** | 780 x 600 |

| Connected Load (KW) | 5,5 KW | 7,5 KW | 11 KW |

** at keyway length 600 machine height = 1310 mm

*** at keyway length 600 machine table L1 = 780 mm x B1 = 600 mm

Find appropriate tools in section tools / service.

We provide a large range of equipment, tools, and accessories.

Keyseating tools / Cutters in original condition for your FRÖMAG machine.

Indexing tables

Type »Rapida CNCE«

Type CNCE-70

Type CNCE-125

- Type »Rapida CNCE« Features

- Type »Rapida CNCE«Technical details

- Type »Rapida CNCE« Tooling and additional equipment

Identical with Rapida E with additional features:

-

Contoured keyways fully programmable

-

Helical keyways

-

Tool retraction

-

Benefit of the FRÖMAG clamping system:

FRÖMAG clamping systems feature a variable height setting in the equipment in order to react flexibly to the vast variety of workpieces.

Options:

- Automation

- Interlinking

- Clamping bridge

- Indexing tables

- Machine data via OPC-UA

- RFID Tagreader

Please contact us for further information.

| CNCE 70 | CNCE 100 | CNCE 125 | CNCE 150/200 | |

| Keyway width (mm) | 2 – 70 | 2 – 100 | 2 – 125 | 6 – 150 6 – 200 |

| Keyway length (mm) NL | 600/750/1000 | 600/750/1000 | 600/750/1000 1250/1500 |

1000/1250/1500/ 1800/2000 |

| Bore size | 10 – 500 | 10 – 500 | 10 – 500 | 20 – 750 |

| Cutting- and Return Speed (m/min) | 0 – 38 | 0 – 38 | 0 – 38 | 0 – 38 |

| Infeed rate / stroke (mm) | 0,01 – 2 | 0,01 – 2 | 0,01 – 2 | 0,01 – 2 |

| Loading Capacity (kN) | 300 | 350 | 350 | 400 |

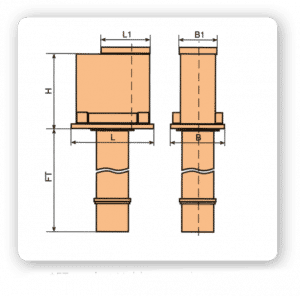

|

Machine Dimensions H

|

1290 1285 810 |

1290 1285 810 |

1290 1285 810 |

1305 2135 1115 |

| Machine Table Size L1 x B1 (mm) | 800 x 600 | 800 x 600 | 800 x 600 | 2100 x 900 |

When using indexing tables TA 680 and larger sizes machine table dimensions will change

| Keyway length | foundation depth |

| 70/750/1000 | 745/995 |

| 100/125/600 | 595 |

| 750 | 745 |

| 1000 | 995 |

| 1250 | 1245 |

| 1500 | 1495 |

| 150/200/1800 | 2650 |

| 150/200/2000 | 2850 |

All dimensions in mm

Find appropriate tools in section tools / service.

We provide a large range of equipment, tools, and accessories.

Keyseating tools / Cutters in original condition for your FRÖMAG machine.

Indexing tables

Broaching machines

Type FSR

Type FSR – MZ

Type FTR

FRÖMAG electromechanical vertical internal broaching machines FSR, guarantee high efficiency and low production cost due to their special design. The pull bridge of the machine is designed to accept broach holders according to the different standards. The ball screws used for the stroke movement of the pull bridge as well as the additional hardened and ground guide columns, result in a connection with the DC-motors for a smooth and rigid running performance of the machine.

Additional equipment offered such as the retriever, shim control, and moveable table, ease machine operation and facilitate automatic machine performance as well as the use of machines in transfer lines.

Highlights:

- Highly productive

- Economic

- Space saving

- Versatile

- Fully automated operating cycle

- Remote support interface

Options:

- Automation

- Side loading in addition to the front door from left, right, or left and right

- Machine data via OPC-UA

- RFID Tagreader

| Machine Type | Stroke (mm) | Pulling force (kN) | Connected load (KW) | Height of the machine table (mm) | Total height incl. MZ (mm) | Basic dimension of the machine B x L (mm) |

| FSR 6 | 800 1000 1250 |

60KN (6t) | 15 KW | 1830 2060 2310 |

3770 4270 4770 |

900 x 1040 |

| FSR 9 | 1000 1250 1500 |

90KN (9t) | 25 KW | 2060 2310 2560 |

4270 4770 5270 |

900 x 1040 |

| FSR 18 | 1000 1250 1500 2000 |

180KN (18t) | 40 KW | 2060 2310 2560 3060 |

4270 4770 5270 5770 |

900 x 1040 |

| FSR 28 | 1250 1500 1750 2000 |

280KN (28t) | 60 KW | 2515 2765 3015 3265 |

4470 4970 5470 5970 |

1320 x 1410 |

Subject to change without notice

Contrary to conventional broaching machines, the broaching tool stays stationary and the moving table including the workpiece and workpiece clamping is moved relative to the broaching tool. FRÖMAG electromechanical driven FTR broaching machines ensure cost effectiveness and efficiency. Because of the ergonomic construction, the machines can be placed at ground level and do not need a foundation pit. They can be operated without additional platforms or pedestals. The FTR broaching machines can be set up as stand-alone machines with either manual or automated feed. They can also be fully integrated into machining cells applying robotics and handling devices.

Highlights:

- Installable at ground level

- Ergonomic design

- Highly productive

- Economic

- Space saving

- Versatile

- Fully automatic operating cycle

- Remote support interface

Options:

- Automation

- Side loading in addition to the front door from left, right or left and right

- Machine data via OPC-UA

- RFID Tagreader

| Machine | Stroke (mm) | Pulling force (kN) | Connected load (KW) | Height of machine table (mm) | Total height |

Basice dimensions |

| FTR6-01 | 1000 1250 |

60kN (6t) | 25 KW | 940 mm | 3060 3360 |

1700 x 1230 mm |

| FTR9-01 |

1000 |

90kN (9t) | 30 KW | 940 mm | 3060 3360 |

1700 x 1230 mm |

| FTR10-11 | 1500 2000 |

100kN (10t) | 30 KW | 1060 mm | 4100 4600 |

2100 x 1430 mm |

| FTR20-11 | 1500 2000 |

200kN (20t) | 55 KW | 1060 mm | 4100 4600 |

2100 x 1430 mm |

| FTR30-11 | 1500 2000 |

300kN (30t) | 80 KW | 1140 mm | 4100 4600 |

2520 x 1600 mm |

Subject to change without notice

Special machines

- »Short broaching machine« Features

- »Short broaching machine« Technical details

- »Short broaching machine« tooling and additional equipment

FRÖMAG’s latest development is an economical broaching procedure that is executed with short broaches in multiple passes using FRÖMAG’s short broaching machine. The short broaching procedure is protected by patent rights.

Advantages:

- The broaching operation is fully automatic

- Elimination of complex setups and setup times

- Significant reduction of space (broaching tool is significantly shorter when compared to a standard broaching tool)

- The cutting insert will have an extended tool life due to being made exclusively with a high quality PM-material

- Improvement of the machined keyway surfaces due to the rigidity of the electromechanical drive used in the FRÖMAG short broaching machine

- Fast broaching and return speeds result in higher productivity and lower costs

- Operation of the machine is conducted interactively using common language, not computer language. No special computer or programming skills are necessary as the operator is guided through the programming by easily followed Menuees

| 4-600-APC | 7-600-APC | 7-750-APC | |

| Keyway width (mm) | 32 | 50 | 70 |

| Stroke length / Keyway length (mm) | 425/200 | 600/200 | 750/200 |

| Bore sizes | 10 – 130 | 10 – 230 | 10 – 350 |

| Broaching- and Return Speed (m/min) | 0–10/20 | 0–10/20 | 0–10/20 |

| Connected load of the Main drive (kW) | 15 | 22 | 22 |

| Infeed rates / stroke (mm) | abhängig vom Räumwerkzeug | abhängig vom Räumwerkzeug | abhängig vom Räumwerkzeug |

| Machine loading capacity (kN) | 300 | 350 | 350 |

|

Machine dimensions

|

1290 1285 810 – |

1290 1285 810 595 |

1290 1285 810 745 |

| Machine table L1 x B1 (mm) | 800 x 600 | 800 x 600 | 800 x 600 |

The tools are custom designed and produced.

- Electromechanical horizontal slotting machine Features

- Electromechanical horizontal slotting machine In use

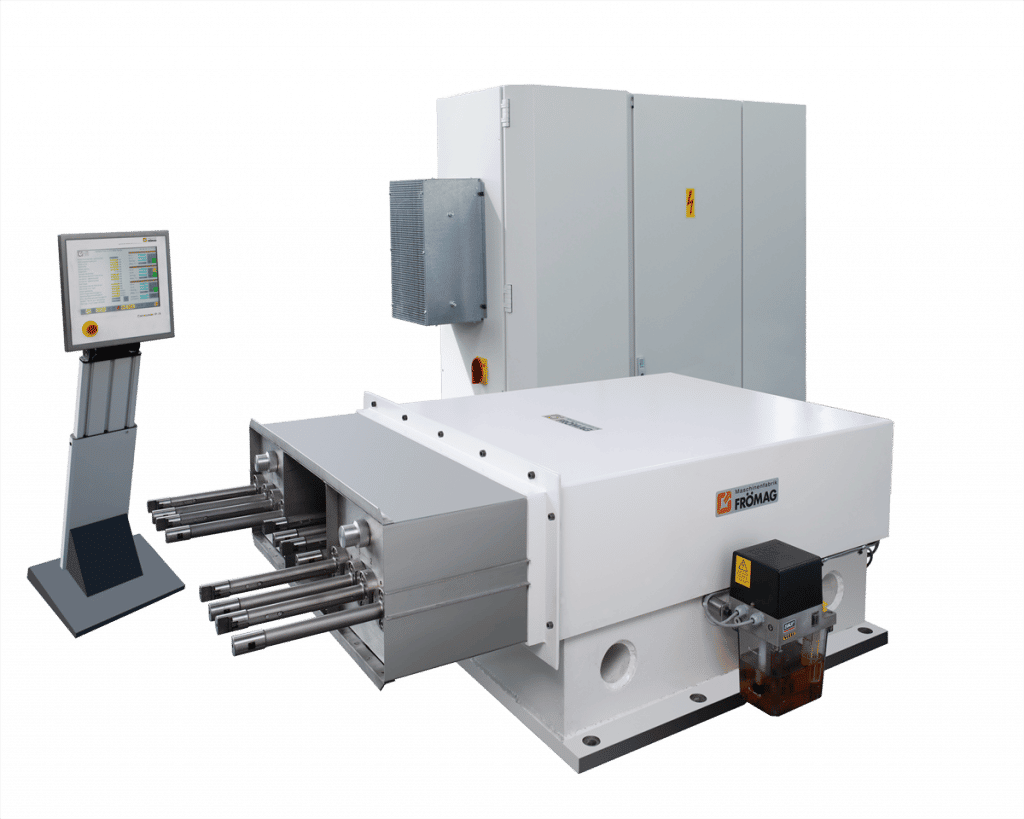

Electromechanical horizontal slotting machine for machining cylinder crank cases

This range of machines is preferably used in transfer lines to machine keyways in cylinder crank cases with a maximum of twelve simultaneously working slotting tools.

These machines are custom designed and produced.

This unit consists of three slotting aggregates with four slotting tools.

When machining a six-cylinder crank case, all twelve slotting tools are oscillating in an axial direction. When machining a four-cylinder crank case, one slotting unit is stopped so that only eight tools are in circuit.

This model range is especially used for:

- Use in transfer lines

- Machining of cylinder crank cases

- Customized applications

See the basic technical procedures of the original FRÖMAG machines.